For example, from the table top:

Water 3 mm

Track bed 39 mm

Track bed + ballast 42 mm

Platform 51 mm (excluding 2 mm finishing layer)

Space between rails 44 mm (station)

Sidewalks 51 mm

Front road (loading and unloading) 46 mm, etc.

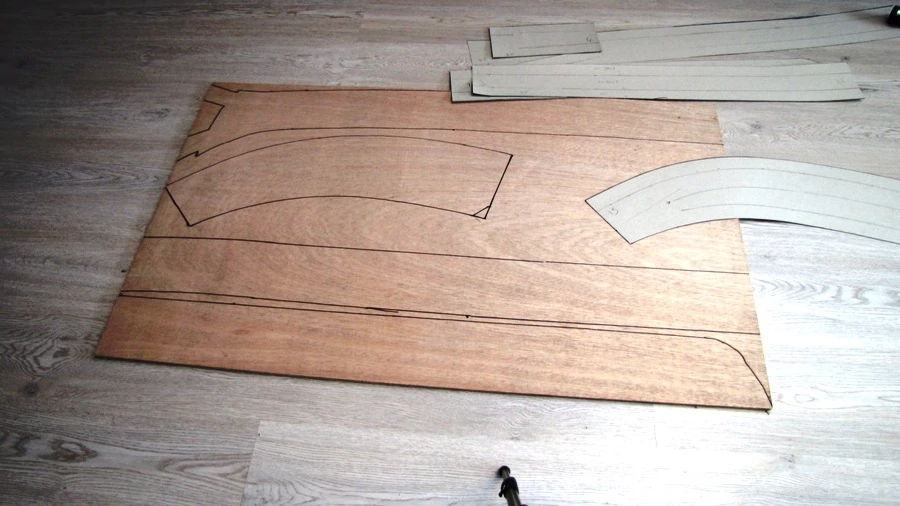

After the track has been cut out of a 9mm plate, 3cm thick styrofoam is cut out. The cut-out wooden track then serves as a template. To be able to cut styrofoam, you can make a cutter yourself. There are enough examples of this on the internet/youtube. I purchased a small cutter for thirty euros and made a cutting table with some leftover planks. This works excellently, especially since the cutter can easily be taken off the cutting table and used by hand. An adjustable guide with clamps and you can cut straight.

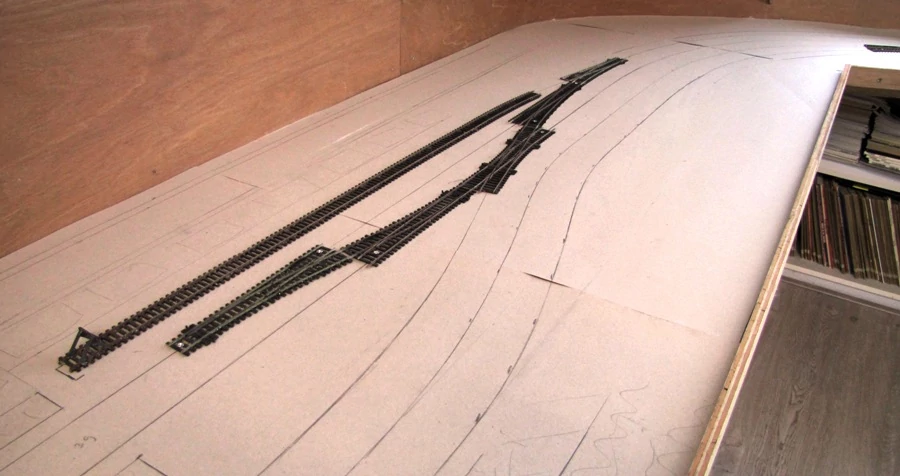

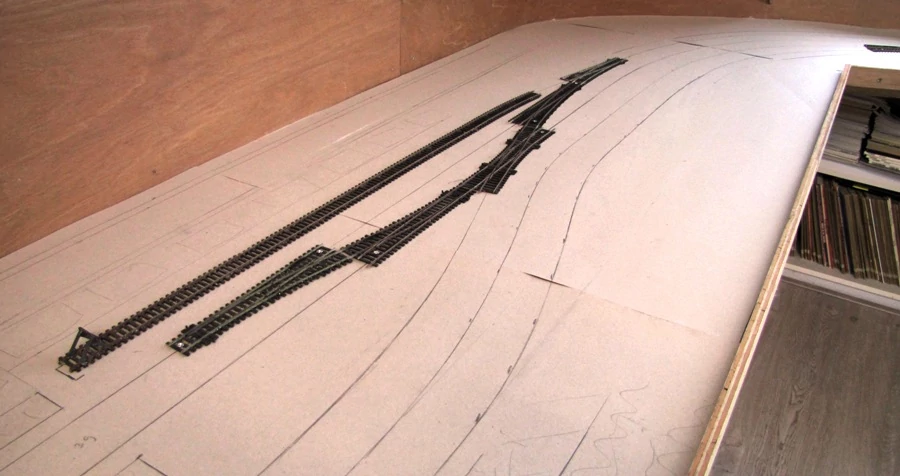

Optionally, these can be cut along the rails before ballasting takes place. For now, there is plenty of room to make corrections. Below, all tracks have been laid and connected. All switches are functioning. Now it is time to extensively test drive, especially with all possible long trains. No wagon may come loose or derail. If this does happen, the track may not be completely level. Repairing after ballasting is no longer possible, so everything must be 100% in order before we finish the rails definitively.