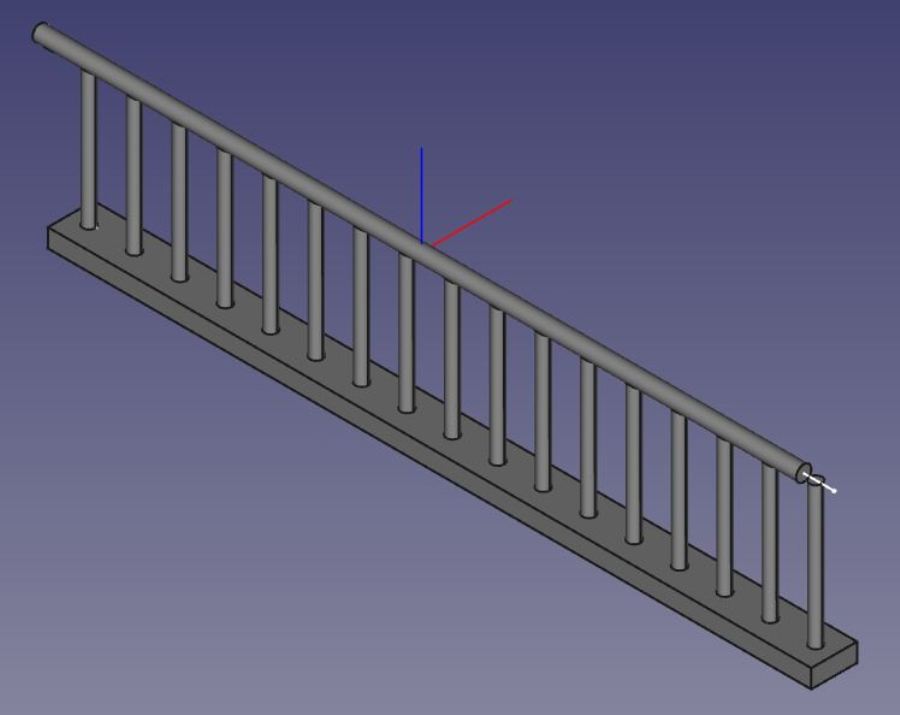

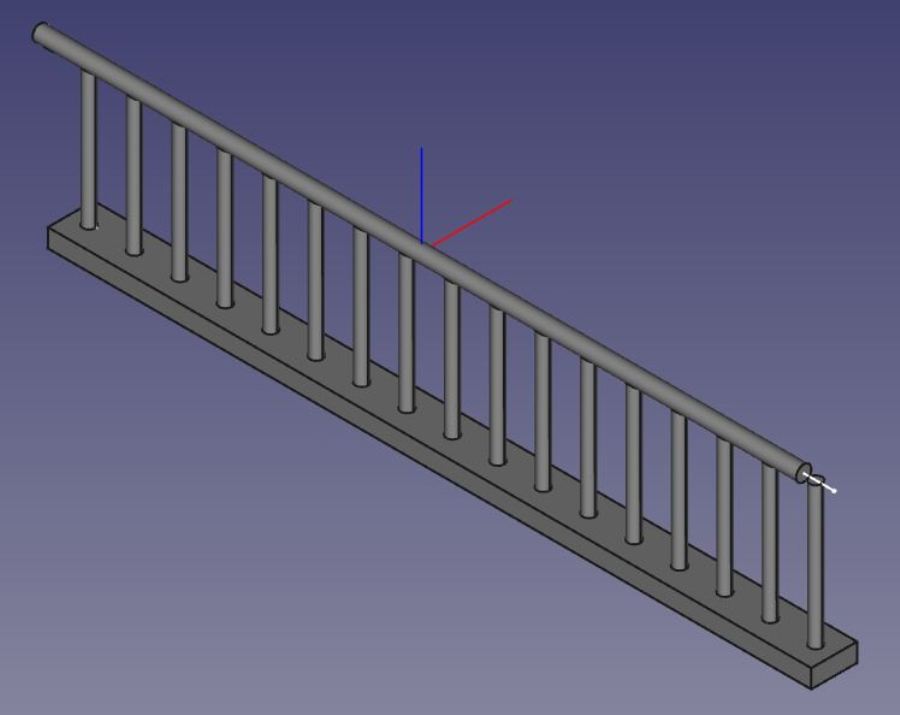

For the printer, I chose the SLA/DLP technique. This method involves using a liquid plastic resin that hardens when exposed to UV light. This technique provides the finest level of detail in model building. Most printers come with slicing software included, and the "Anycubic Ultra" printer that I chose is no exception. This software can modify the 3D design from the CAD program so that the printer can work with it. Configuration options such as layer thickness and exposure time to UV light can be adjusted. The software slices the design into layers that are printed sequentially. Typically, the included software may have some limitations. However, there is also a free version of the "Lychee Slicer" program available. This program provides everything a good slicer needs. The second screenshot is of a modified CAD design from Lychee Slicer. The fence can be easily duplicated. One major advantage of the latter software is the ability to save your used settings in Lychee. As a new user, you can easily select the most commonly used and successful settings, minimizing the chances of misprints, provided that your printer model is included in the program.

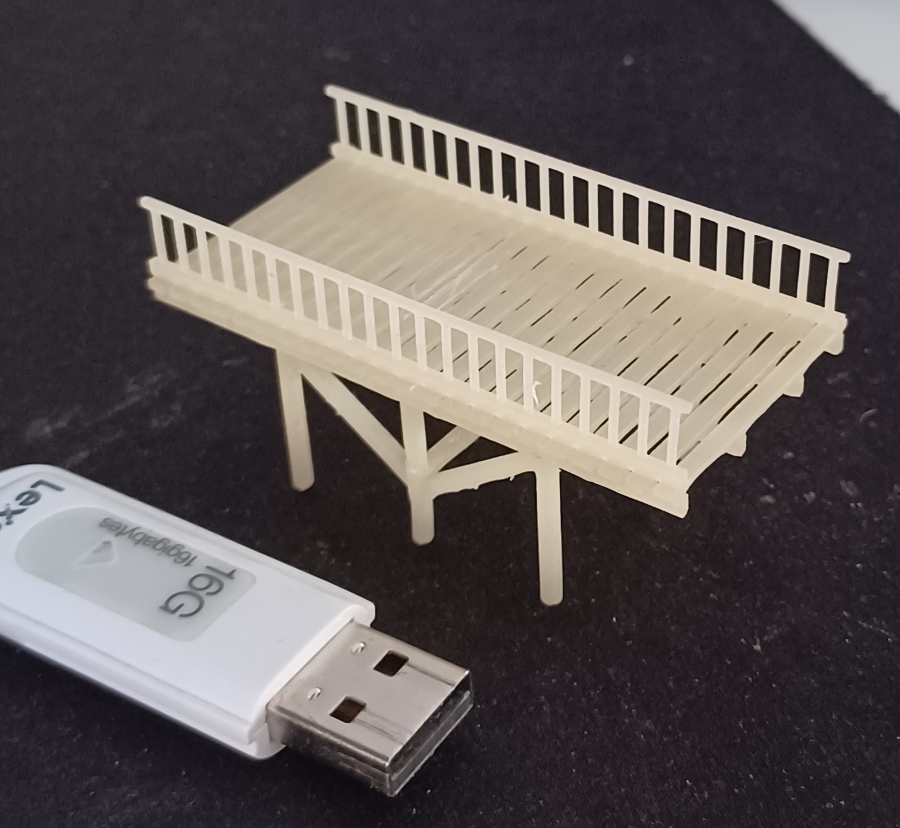

The next project can be seen in picture four. It is a small bridge that needs to be placed over a little ditch. After the fences, this is the second little project. In picture five, you can see how the bridge came out of the printer.

Now that all the small projects have been successfully completed, I'm going to try something bigger. My model layout is primarily a train station, and a station definitely needs some platform canopies. Since these kits can be quite expensive and I need four of them, this seems like a fun project to me. Of course, this won't fit in the printer all at once, so multiple different prints need to be made and assembled together using some Polystyrene.